Innovation

Powers Growth

Powers Growth

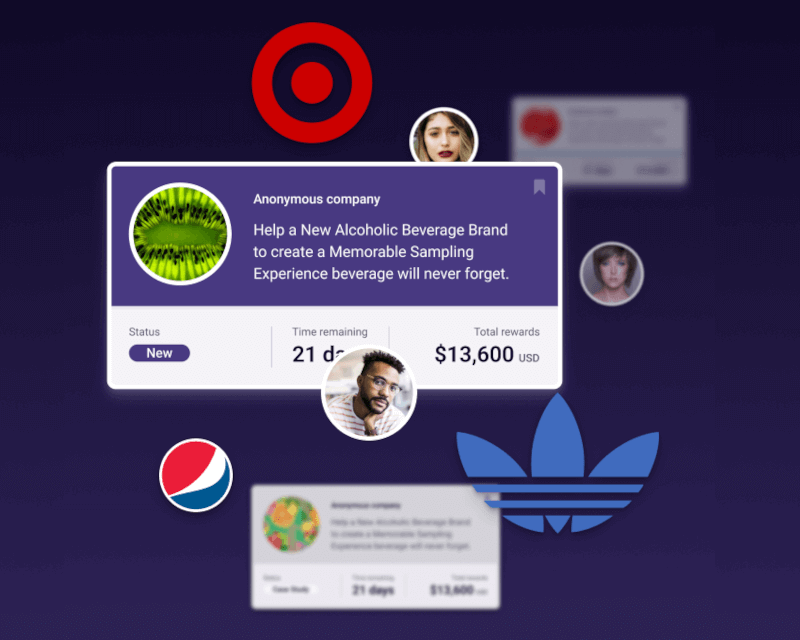

MindSumo helps companies crowdsource breakthrough ideas & insights from a global community of creative problem solvers

MindSumo Journey

A Challenge

Is Launched

Is Launched

Challenges are created with expert assistance from MindSumo to ensure success

Problem Solvers

Submit Ideas

Submit Ideas

Engage problem solvers based on skills, location, experience and other criteria

The Challenge

Is Reviewed

Is Reviewed

Submissions are rated & reviewed with assistance from a dedicated Challenge Manager

Problem Solvers

Are Rewarded

Are Rewarded

The best ideas & insights receive rewards distributed through the MindSumo platform

Experience Mindsumo from our Users

Learn more about how you can leverage Challenges in your day-to-day from users like you.

Our Results in Numbers

$1.3m+

Money Rewarded

1300+

Challenges Launched

200+

Active Countries

Our Clients

Get Started

MindSumo helps companies crowdsource breakthrough ideas and insights from a global community of creative problem solvers